|

|

|||||||||

|

|||||||||

|

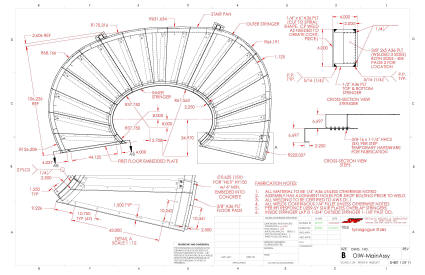

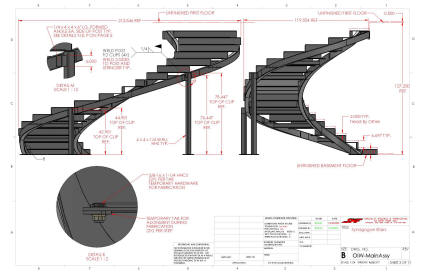

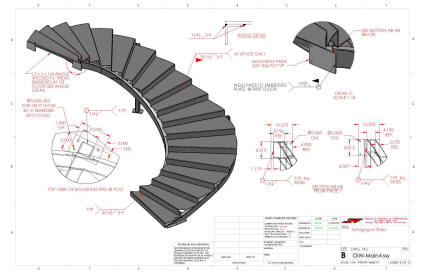

Curved Metal Staircase For Synagogue in Brooklyn, NY This project called for a curved metal staircase for the synagogue's main entrance, a high-traffic area. The architect's specifications called for two complex sweeps, multiple radius dimensions and architectural integration with the existing structure. Our manufacturing engineers designed template and fixtures to enable the fabrication team to work quickly and accurately. Our experience in creating curved staircases for retail, industrial and institutional installations helped us to bring this project in on-time and on-budget.

Call us at 800-896-7886 or email us for questions or a quote on your project. Click here to return to the Curved Staircases and Architectural Fabrications page

|

|||||||||

|

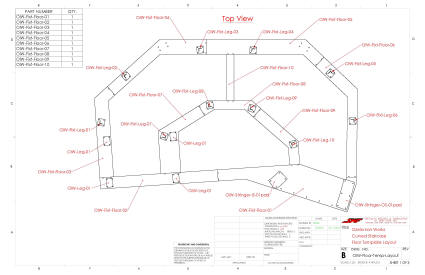

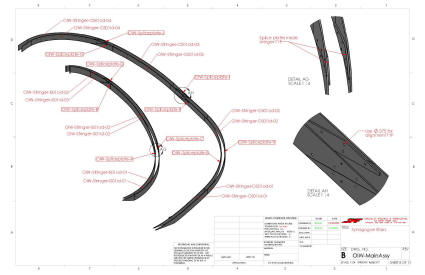

Our engineers render your 2D blueprints into 3D images utilizing high-end workstations and advanced software programs. At this stage we often catch manufacturing problems with the design that we can overcome by collaborating with the architects. Now that the engineers have given the fabrication team the blueprints to work with, we can see the above stairs being built from the ground up. Engineers designs the floor template (as you can see in the picture above) later we will add fixtures as a support for the upcoming assembly After the drawings are made up by the engineers, they are sent to our state of the art laser cutting machines. We currently have 2 laser's as well as a water jet that cut with the highest of precision Above is what the floor template drawing looks like after being cut out by the laser. This will be the base which the curved staircase will be built upon. From the floor template the engineers design fixtures that will connect to the base and provide support for the upcoming assembly Our projects are monitored with ongoing quality control protocols throughout the fabrication process. Our precision lasers have cut and shaped the stringers to the specific radius of the ellipse The steel stringers being shaped by our highly experienced fabricators After being shaped the stringers are cut from the sheet of steel We design and specify each individual part, enabling our trained professional's to create whatever our customers desire with exact specifications The first side of the stringer is attached to the fixture The steps have been cut with one of our lasers, shaped, and numbered. They are now ready for installation The high-end workstations with powerful software we utilize guarantee that every piece fits perfectly. Before the assembly is done on the floor we assemble everything on the computer, eliminating guesswork and saving manufacturing time. Installation of the steps creates the exact shape of the staircase. Going up... ... ... Completing fit up of box tube Next, the steps are removed for cleaning; we then weld the stringer tube

|

|||||||||

|

Specialty Welding &

Fabricating of NY, Inc. 1025 Hiawatha Blvd. E., Syracuse, NY 13211

© 2010 Specialty Welding & Fabricating of New York, Inc. |

|||||||||